Concentrating Solar Power (CSP) – Embracing the Sun’s heat

By Eng (Dr.) S. Witharana

Sri Lanka is blessed with plentiful sunlight year-round. The Global Horizontal Irradiance (GHI), which is the universal measure for solar intensity, varies between 1,247 kWh/m2 to 2,106 kWh/m2 [1]. According to a recent study jointly conducted by the UNDP and ADB, Sri Lanka has the potential to deploy 16 GW of solar power [2]. It is in this backdrop the government has accelerated its drive for solar-powered electricity. For instance, “සුර්ය බල සන්ග්රාමය” (battle for solar energy) project aims to add 200MW of solar electricity by 2020 and 1000MW by 2025 [3]. By 2030 the government plans to generate 70% of electricity demand using renewable energy [4] where solar can become a major contributor. The USD 100M solar energy project to power state institutions [5], 100MW solar tender for power projects ranging in size from 3MW to 10MW [6], and 100MW Solar Park under construction in Monaragala [7], are further examples for large scale projects spearheaded by the government. Nearly all these projects are based on solar photo voltaic (SPV) technology, where the PV panels are to be imported from abroad and mounted on rooftops. While appreciating the SPV’s positives, one should also recognize the country’s potential for solar thermal power generation. At the moment however, solar thermal applications are limited to commercially available rooftop water heaters and a small number of low-capacity food driers. According to Sustainable Energy Authority’s website, up to 30 June 2020, there were only two permits issued for “Solar Thermal” plants, each with a capacity of 10MW [8].

To ensure power system stability, reliability, and cost effectiveness, Sri Lanka may have to move towards Concentrating Solar Power (CSP) technologies. This article intends to present an overview of the CSP for electrical power generation, and to show future directions.

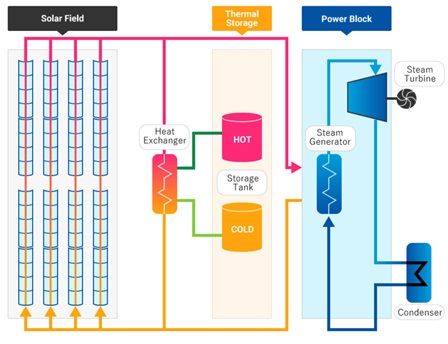

Concentrating solar power is the concept of using direct solar radiation to heat a fluid and generate electricity. A modern CSP plant layout (figure 1) comprises of three sections; Solar field (to convert solar energy into thermal energy), Thermal storage (to store thermal energy using a heat-storage medium), and a Power block (to generate electricity through a conventional steam turbine). The heat transfer fluid (eg; a synthetic thermal oil or a molten salt) absorbs heat from solar field and travels to the power block. Water in the steam generator absorbs this heat, becomes steam and turns the steam turbine, to generate electricity. HTF thereafter returns to the solar field, so the cycle continues. The excess heat meanwhile is directed to the thermal storage section for future use.

Figure 1: CSP plant layout (image courtesy: chiyodacorp.com)

Let u snow take a closer look at the operation of a CSP plant.

A) Solar Field

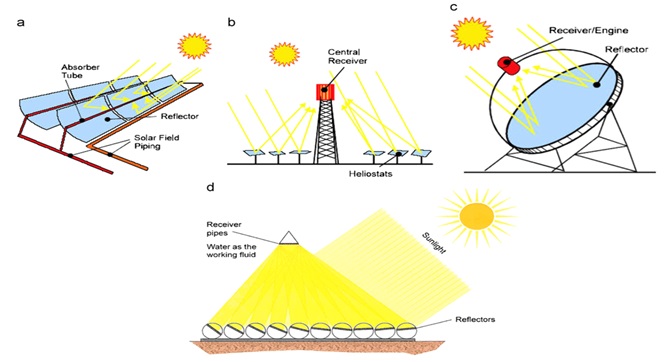

The solar field consists of a concentrating system. There are four types of them currently in use. These are illustrated on figure 2

Figure 2: Solar concentrators: (a) parabolic trough (b) power tower (c) dish-engine (d) Linear Fresenel [9].

Parabolic trough systems use curved-shape reflectors to focus sunlight onto an absorber tube placed in their focal line. The reflectors can track the sun along one axis, predominantly north-south, to ensure that the HTF in the absorber tube attains temperatures as high as 400°C. Trough systems are the most advanced and matured CSP system nowadays, with nearly 70% of the world’s operating CSP power plants falling into this category.

In a power tower system, the flat reflectors with two-axis sun tracking concentrates sunlight on to a central receiver at the top of a tower. HTF in the receiver absorbs the thermal energy and increases its temperature close to 1000°C. Power tower is the second most-popular CSP system at present.

A dish-engine system comprises of a reflective dish with two-axis sun tracking, and a receiver mounted at the focal point of the dish. The receiver is filled with a gas (the HTF) and connected to an engine, such as Brayton turbine, organic Rankin engine, reciprocating steam engine, or Sterling engine. Despite being the least popular among CSP systems, Dish-engine systems are the most efficient with an annual solar-to-electric efficiency ranging from 16% to 18%.

Linear Fresnel system is an array of nearly flat linear reflectors that focuses the sunlight on to a single receiver fixed on a linear tower. Water, which is the HTF in the receiver, absorbs heat and becomes steam that subsequently runs a steam turbine. Employs one axis sun tracking, similar to parabolic trough systems.

B) Thermal Energy Storage

Solar intensity fluctuates in nature and so would the power production from a CSP plant. A thermal energy storage (TES) system can eliminate this uncertainty and ensure steady and reliable power supply. The TES concept is to capture and store the heat when it is available and release it when it is desirable. TES technologies can be categorized into three classes as follows.

Sensible thermal energy storage (STES)

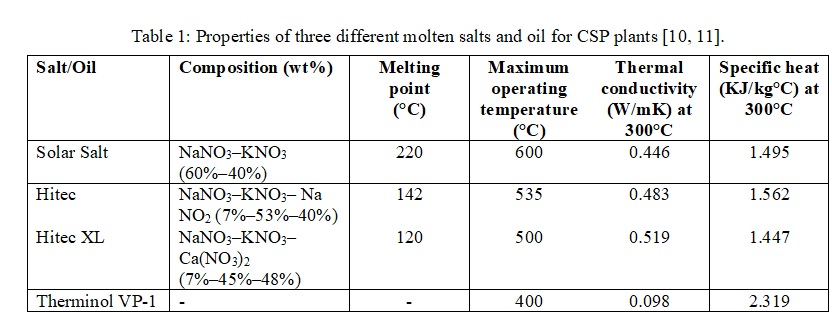

STES category comprises of materials that can store and release heat by changing its temperature. Solid STES materials include concrete, ceramics, fire bricks and ferroalloy materials. They possess high thermal conductivities and high operating temperatures up to 1200°C. However, the downside is their low heat capacities. On the other hand, liquid STES materials are superior in heat capacity but poor in thermal conductivity. Table 1 presents the most popular liquid STES materials. Noticeably the molten salts are taking over from synthetic oils (eg; Therminol VP-1), which were commonly used before.

If the demand for salts continue to rise, that might create a shortage of nitrates for conventional applications such as fertilizer manufacturing.

Latent thermal energy storage (LTES)

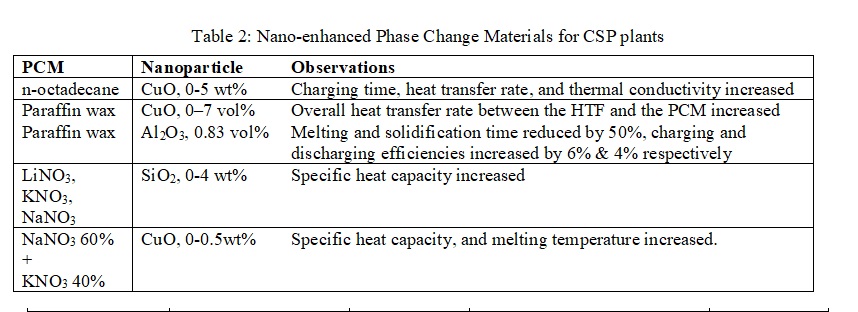

LTES systems are based on phase change materials (PCM), which change their phase from solid to liquid and vice versa, to store and release heat respectively. They can reach higher energy storage densities than STES systems, thereby requiring smaller storage tanks. Eutectic molten salts, inorganic salts, and metals & metal alloys are being considered for PCMs. The main disadvantage with PCMs is their low thermal conductivities, which leads to lower melting and solidification rates. This problem has been addressed by introducing nanoparticles into the PCM, as evident from Table 2.

Thermochemical thermal energy storage (TTES)

Thermochemical TES systems store and release thermal energy through chemical reactions. Consider equation (1) for instance. During the charging process, the heat is absorbed by the reactant AB, resulting in dissociation of two parts into A & B. In the discharging process, the two products A & B are recombined, and heat is released.

AB + Heat ![]() A + B (1)

A + B (1)

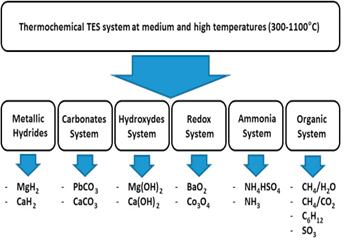

Advantage of TTES is that, they are lower in thermal losses and higher in volumetric energy densities than STES and LTES systems. Figure 3 portrays potential TTES materials for CSP applications.

Figure 3: Six candidate thermochemical storage systems at temperatures of 300– 1100 °C [10].

Figure 3: Six candidate thermochemical storage systems at temperatures of 300– 1100 °C [10].

A summary and the outlook

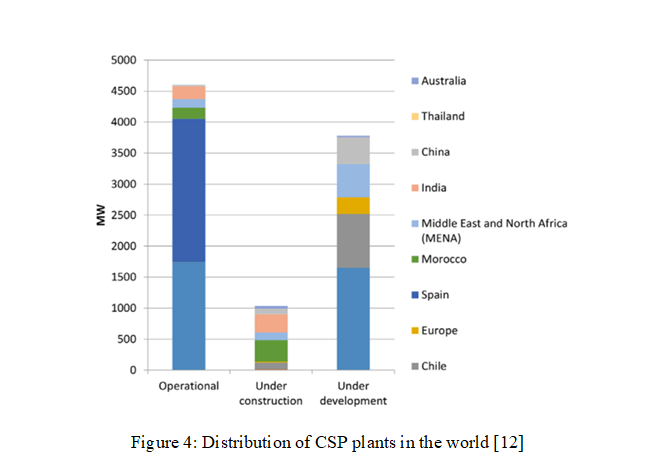

By mid-2018, there were 140 CSP projects operating around the world. 98 of these were fully functional plants, while the remaining 42 were either under construction or development. Figure 4 reveals the geographical distribution and installed capacity of these plants.

With fast-depleting fossil fuel resources and global environmental concerns, the Middle East is engaged in an ambitious drive to cross-over to Solar-powered electricity.

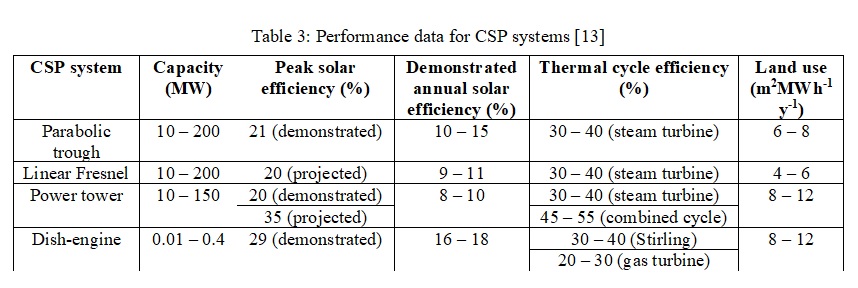

Performance data for CSP systems are presented in Table 3. Notably the Dish-engine systems have demonstrated the highest annual solar efficiency. However, their capacities are small, land use is large, and therefore are used for stand-alone applications in remote areas.

In the meantime, the Power tower systems are gaining popularity despite the large land use. Main reasons are the elimination of long piping networks around the solar field, and, flexibility with heat transfer fluids. For instance, power tower projects nowadays use a single molten salt for both the HTF and TES media.

In the research front, there have been considerable efforts to develop novel thermal storage technologies, increase plant efficiency, improve reliability, and lower the unit production cost. Supercritical CO2 cycle, high temperature & non-corrosive molten salts, iron oxide & silica particles as solid STES, high absorptivity coatings, and dust-free reflector surfaces are some of the specific areas where the industry and academia are focusing on.

Bibliography

- http://powermin.gov.lk/bfse/?services=annual-global-horizontal-irradiation-ghi-in-sri-lanka-by-sea

- https://www.pv-magazine.com/2020/03/09/sri-lanka-launches-150-mw-solar-tender/#:~:text=According%20to%20a%20recent%20joint,demand%20with%20renewables%20by%202050.

- http://www.energy.gov.lk/en/soorya-bala-sangramaya

- https://www.presidentsoffice.gov.lk/index.php/2020/09/14/70-of-electricity-demand-will-be-generated-using-renewable-energy-by-2030/

- https://economynext.com/sri-lanka-approves-usd-100mn-solar-energy-project-to-power-state-institutions-70663/

- https://www.pv-magazine.com/2020/03/09/sri-lanka-launches-150-mw-solar-tender/#:~:text=According%20to%20a%20recent%20joint,demand%20with%20renewables%20by%202050.

- http://www.energy.gov.lk/en/renewable-energy/energy-parks

- http://www.energy.gov.lk/images/energy-management/energy-permit-issued-renewable-energy-projects.pdf

- I. Purohit and P. Purohit, "Techno-economic evaluation of concentrating solar power generation in India," Energy Policy, vol. 38, no. 6, pp. 3015-3029, June 2010.

- 10. M. Liu et al., "Review on concentrating solar power plants and new developments in high temperature thermal energy storage technologies," Renewable and Sustainable Energy Reviews, vol. 53, pp. 1411-1432, January 2016.

- D. Kearney et al., "Overview on use of a Molten Salt HTF in a Trough Solar Field," NREL Parabolic Trough Thermal Energy Storage Workshop, Golden, Colorado, 20-21 February 2003.

- M. T. Islam, N. Huda, A. Abdullah and R. Saidur, "A comprehensive review of state-of-the-art concentrating solar power (CSP) T technologies: Current status and research trends," Renewable and Sustainable Energy Reviews, vol. 91, pp. 987-1018, August 2018.

- H. Müller-Steinhagen and F. Trieb, "Concentrating solar power- A review of the technology," Ingenia, vol. 18, January 2004.

Eng (Dr.) S. Witharana

Eng (Dr.) S. Witharana

PhD (UK), CEng MIE(SL)

Eng (Dr) S. Witharana holds a BSc in Mechanical engineering, MSc in Energy technology, and PhD in Nano thermal engineering. He works for the Department of Mechanical Engineering, University of Moratuwa. He was a member of the IESL’s Mechanical engineering sectional committee, Young Members’ Section, Governing Council, and is currently serving as a member of the IESL Education Committee.